How to ensure the safety of battery packs in high temperature?

Understanding Thermal Runaway and Its Risks in Battery Packs

Thermal runaway in lithium-ion battery packs occurs when heat generation outpaces dissipation, triggering a self-accelerating failure cycle. This phenomenon accounts for 38% of high-temperature battery failures (Energy-Storage.news 2023), particularly in electric vehicles and grid storage systems where operational demands amplify risks.

What Triggers Thermal Runaway in Battery Packs?

Common triggers include:

- Physical damage to cell integrity (e.g., punctures from manufacturing flaws)

- Electrical abuse such as overcharging beyond 4.25V per cell

- Ambient temperatures exceeding 45°C (113°F)

At 80°C, separator materials begin degrading, enabling internal short circuits (source: Discovery Alert 2024). This can rapidly escalate temperatures to 500°C within seconds, releasing flammable electrolytes and increasing fire risk.

Heat Generation vs. Dissipation: Balancing Cell-Level Thermal Dynamics

Effective thermal management requires maintaining a heat dissipation rate 2–3 times higher than generation. Key design factors influence this balance:

| Design Parameter | Impact on Thermal Balance |

|---|---|

| Electrode thickness | Thicker electrodes increase internal resistance by 15–20% |

| Cell spacing | Gaps under 3mm reduce heat dispersion efficiency by 40% (Nature 2023) |

| Coolant flow rate | Each 1L/min increase lowers peak temperature by 8–12°C |

Passive cooling systems often fail in environments above 30°C, making active thermal controls essential for high-performance applications.

Using TRF (Thermal Runaway Factor) to Assess Safety Risks

The Thermal Runaway Factor (TRF) quantifies risk using the formula:

TRF = (Heat Generation Rate) / (Heat Dissipation Capacity)

Systems with TRF >1.2 have an 85% probability of cascading failures (Energy-Storage.news 2023). Modern designs incorporating real-time TRF monitoring reduce high-temperature incidents by 72% through predictive current throttling and staged cooling activation.

Battery Cell Design for Enhanced Thermal Stability

Electrode and electrolyte materials for high-temperature resilience

Battery packs today incorporate materials that stand up better to heat, making them safer overall. The newer ones often have cathodes rich in nickel along with anodes containing silicon, which actually handles the heat pretty well without cutting down on how much energy they can store. Manufacturers also use separators coated with ceramic material and electrolytes that won't catch fire easily to stop those dangerous short circuits inside. Lithium iron phosphate, or LFP batteries, are another big improvement because they cut down the risk of overheating problems by around 40 percent when compared to older battery types. All these improvements mean batteries can keep working properly even when temperatures climb past 60 degrees Celsius, something that matters a lot for electric vehicles and large scale energy storage systems where heat management is always a concern.

Structural innovations that prevent thermal propagation

Engineers limit thermal spread using 3D electrode architectures and compression layers that manage expansion forces. Internal firewalls made from aerogel insulation isolate overheating cells, while unified cell-to-pack designs eliminate thermal bridging. Together, these features contain heat at the source without compromising energy capacity.

Case Study: Redesigned lithium-ion cells for improved thermal performance

In 2023, one major manufacturer came out with a redesigned product that really highlighted how good integrated improvements can be. They took pouch type cells and paired them with some pretty impressive thermal management tech, which resulted in about 15 percent more energy density packed into the same space. What's interesting is that even when pushing through 3C fast charging rates, these units kept their surface temps under control, staying at 45 degrees Celsius or lower throughout operation. When they ran accelerated aging tests on these new designs, something stood out: there was roughly 30% less loss in battery capacity after going through 1,000 charge cycles at 55°C conditions compared to what we saw in previous versions from the same company.

Battery Management System (BMS): Real-Time Protection in Hot Conditions

Modern battery management systems (BMS) act as the central nervous system for battery packs operating in high-temperature environments. Through real-time monitoring and adaptive safety protocols, they mitigate risks when ambient conditions exceed safe thresholds.

Continuous Temperature Monitoring and Automatic Shutdown Features

Modern battery management systems (BMS) rely on spread out temperature sensors that check each cell's condition as often as 100 times every single second. If these temperature readings start getting dangerously close to the red zone, which happens when they go over around 60 degrees Celsius for most lithium ion batteries, the BMS kicks into action with several layers of defense. First it might slow down how fast the battery charges, then turn on additional cooling mechanisms if needed, and finally shut everything down completely as a last resort. According to field tests conducted across various manufacturing facilities, this kind of layered approach to managing heat issues actually stops about 9 out of 10 potential overheating problems before they cause any serious damage.

Preventing Overcharging and Current Spikes Under High Ambient Temperatures

Elevated temperatures accelerate electrochemical degradation, increasing vulnerability to overcharge damage. Advanced BMS solutions dynamically adjust maximum charge voltages based on real-time thermal data—lowering thresholds by 3–5% for every 10°C rise above 35°C. Current-limiting algorithms also suppress hazardous spikes during rapid discharge cycles in hot conditions.

Data Insight: BMS Reduces High-Temperature Failure Rates by up to 60%

A 2024 analysis of 12,000 commercial installations found that adaptive BMS technology reduced thermal-related failures by 58% compared to basic voltage-monitoring systems. In environments consistently above 40°C, advanced BMS platforms showed 60–67% greater reliability.

Predictive Algorithms for Early Detection of Thermal Stress

Next-generation BMS utilize machine learning models trained on historical performance and environmental trends. These algorithms detect early signs of thermal stress—such as subtle voltage fluctuations and impedance shifts—predicting potential events 8–12 hours in advance with 89% accuracy. This enables proactive interventions like load redistribution or pre-emptive cooling.

Thermal Management Systems: Active and Passive Cooling Strategies

Effective thermal management systems (TMS) are vital for ensuring battery pack safety and longevity in high-heat conditions.

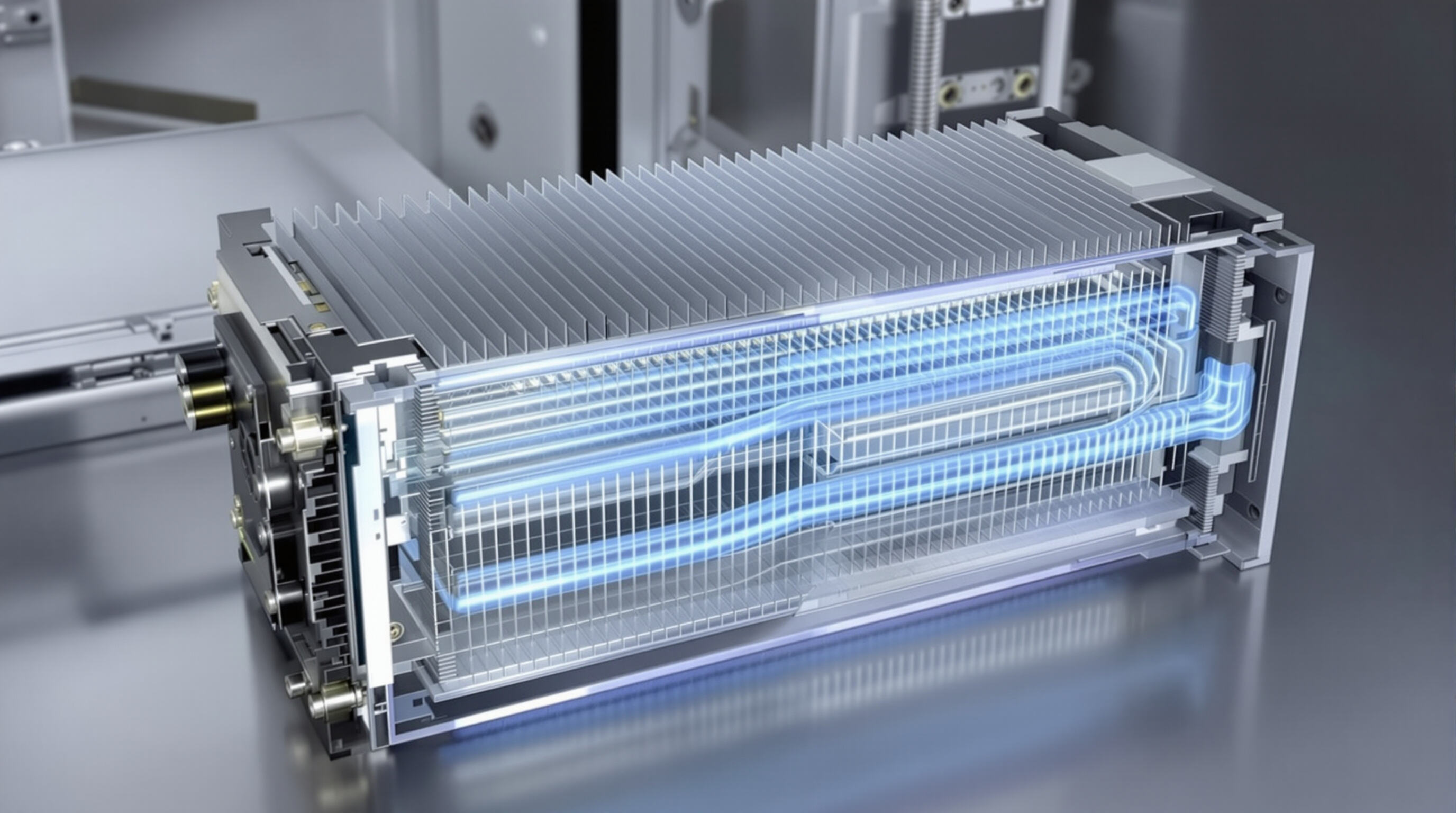

Comparing active vs. passive cooling for battery pack efficiency

Passive cooling works by letting heat escape naturally through things like heat sinks, special materials that change state when hot, or just good old conduction through the enclosure itself. These methods are great because they don't need power and basically take care of themselves, but they really fall apart when dealing with the kind of intense heat generated by tightly packed batteries. Active cooling takes a different approach altogether. It throws fans at the problem, pumps liquids around, sometimes even brings in refrigerants to keep temperatures in check. The downside? These systems eat up about 15 to 25 percent more power compared to passive ones. But what they gain back is worth it for many applications since they can maintain much more consistent temperatures throughout all those battery cells, often improving uniformity by as much as 40 percent.

Liquid cooling trends in EV battery packs for superior heat control

Electric vehicle manufacturers increasingly adopt liquid-cooled systems due to their high heat transfer efficiency. Coolant circulates through microchannels integrated directly into battery modules, removing heat 50% faster than air-cooled designs. This is especially effective for managing the 60–80% higher heat output seen in fast-charging EV batteries.

Designing climate-controlled enclosures to enhance safety

Advanced enclosures combine insulation and active ventilation to stabilize internal conditions. Multi-layer constructions using aerogel insulation and self-sealing barriers reduce external heat ingress by 70% in desert climates. IP67-rated enclosures with automated humidity control are now standard, cutting corrosion risks by 35% in tropical environments.

Best Practices for Charging, Storage, and Safety Validation

Safe Charging Protocols to Prevent Degradation Above 40°C

Charging lithium-ion batteries above 40°C accelerates degradation, with studies showing 3× faster capacity fade compared to operation at 25°C (Ponemon 2023). Recommended practices include:

- Using certified chargers equipped with temperature-monitoring circuits that halt charging at 45°C

- Limiting charge rates to 0.5C when ambient temperatures exceed 35°C

- Maintaining state-of-charge (SoC) between 20–80% to minimize electrode crystalline growth

Optimal Storage Conditions for Battery Packs in Hot Environments

Extended exposure to heat promotes irreversible chemical reactions. A 2024 NREL study found that packs stored at 50% SoC in 30°C environments degraded 40% slower than those kept fully charged at 40°C. Key storage guidelines:

| Factor | Safe Threshold | Risk Beyond Threshold |

|---|---|---|

| Temperature | ≤30°C | SEI layer decomposition |

| Humidity | ≤60% RH | Terminal corrosion |

| State of Charge | 40–60% | Lithium plating |

Validating Safety: Accelerated Testing With ARC and Stress Simulations

Advanced validation methods like Accelerating Rate Calorimetry (ARC) and finite element analysis (FEA) simulate extreme thermal scenarios. UL 9540A-certified testing exposes battery packs to:

- Thermal ramp rates up to 10°C/min

- Mechanical crush forces equivalent to 200% of rated load

- Short-circuit currents exceeding 1,000A

According to a 2023 industry report, these protocols reduced field failure rates by 70% in packs operating above 45°C (UL Solutions).

FAQ Section

What are the main causes of thermal runaway in battery packs?

The main causes of thermal runaway in battery packs include physical damage to cells, electrical abuse such as overcharging, and high ambient temperatures exceeding 45°C.

How is thermal runaway risk measured?

Thermal runaway risk is measured using the Thermal Runaway Factor (TRF), which is calculated as the heat generation rate divided by the heat dissipation capacity. A TRF greater than 1.2 indicates a high risk of failure.

What role does a Battery Management System (BMS) play in preventing overheating?

A Battery Management System (BMS) continuously monitors cell temperature and adjusts charging rates and cooling mechanisms. It can also shut down the pack to prevent overheating.

How effective are active cooling systems compared to passive ones?

Active cooling systems are more effective than passive ones in managing high heat levels. They maintain more consistent temperatures but consume more power.

What improvements have been made in battery cell design to enhance thermal stability?

Improvements include the use of high-temperature resistant materials, 3D electrode designs, and advanced thermal management technologies that prevent thermal propagation.