Key Performance Parameters in Battery Cell Evaluation

Why performance characterization of lithium-ion battery cells matters

Getting good at evaluating how lithium ion batteries perform can stop major problems before they happen across everything from electric vehicles right down to big scale energy storage solutions. According to research published in Nature, around 23 percent of all battery recalls actually come from issues spotted too late during initial tests. When engineers take time to thoroughly characterize these batteries, they get better at guessing how long they'll last through charge cycles, spot problems like the gradual buildup of solid electrolyte interphase (SEI) layers, and make their cooling systems work smarter rather than harder. This kind of detailed analysis makes a real difference in keeping our tech safe and reliable over time.

Fundamental electrochemical parameters: Capacity, open-circuit voltage, and internal resistance

Three metrics form the cornerstone of battery evaluation:

| Parameter | Impact on Performance | Typical Benchmark Values |

|---|---|---|

| Capacity (Ah) | Determines energy storage capability | ±2% variance per 100 cycles |

| Open-Circuit Voltage (V) | Reflects state-of-charge and cell chemistry | NMC: 3.6-4.2V, LFP: 3.2-3.3V |

| Internal Resistance (mΩ) | Governs power delivery efficiency | <100 mΩ for EV-grade cells |

A comprehensive analysis in Joule found capacity retention rates vary by 18–22% across commercial cell types under identical cycling conditions, highlighting the importance of chemistry-specific benchmarks.

Performance benchmarking across chemistries: NMC, LFP, and LTO

Modern battery systems require chemistry-specific evaluation frameworks:

- NMC cells deliver 240–280 Wh/kg energy density but show 15% faster capacity fade versus LFP

- LFP demonstrates 92% capacity retention after 2,000 cycles in stationary storage applications

- LTO achieves an exceptional 20,000-cycle lifespan despite lower 70–80 Wh/kg energy density

These differences underscore the trade-offs between energy density, longevity, and stability when selecting chemistries for specific use cases.

Best practices for reliable and comparable battery cell testing

Four principles ensure test validity:

- Maintain 25±1°C ambient temperature during cycling

- Use NIST-traceable voltage/current measurement tools

- Implement 48-hour stabilization periods between test phases

- Record electrochemical impedance spectroscopy (EIS) data at 10%-90% SOC increments

Adhering to these protocols minimizes measurement drift and enhances cross-lab comparability.

Industry shift toward standardized performance evaluation protocols

Leading laboratories now align with IEC 62660-1 and UL 1973 protocols, reducing inter-lab capacity measurement discrepancies from 12% to 4.5% since 2019. The Joint Battery Testing Consortium recently introduced unified aging benchmarks across 18 battery chemistry variants, enabling more consistent performance reporting across global supply chains.

Core Testing Methods for Battery Cell Performance

Overview of Common Battery Testing Methods Across Industries

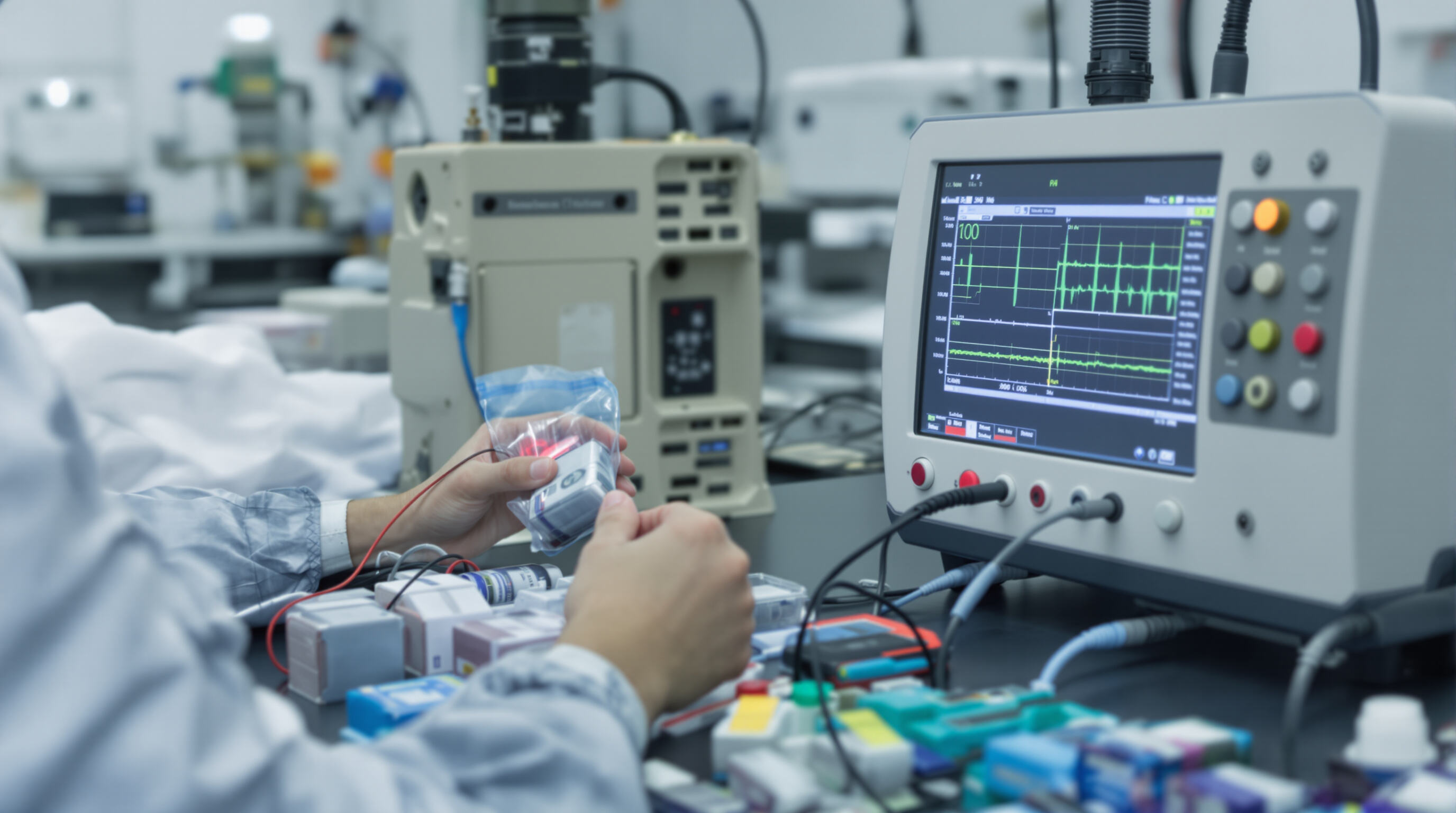

When evaluating modern battery cells, engineers typically rely on three main approaches. First there's galvanostatic charge and discharge testing to measure how much energy the cell can hold. Then comes electrochemical impedance spectroscopy, or EIS for short, which looks at internal resistance issues. And finally, many labs use hybrid pulse power characterization (HPPC) to simulate real world load conditions. These testing methods generate critical information that helps shape products in everything from cars to smartphones. According to recent industry reports, around 89 percent of manufacturers actually combine at least two of these techniques when validating battery performance, showing just how important this multi-angle approach has become in ensuring reliable power solutions across different markets.

Measuring Capacity Through Galvanostatic Charge/Discharge Cycling

This method applies constant-current phases during charging and discharging to calculate capacity (Ah) and energy density (Wh/kg). Recent standardized testing protocols recommend pulse sequences with 20% SOC increments and 1-hour rest periods, reducing temperature-induced measurement errors by 32% compared to traditional continuous cycling.

Case Study: Capacity Testing in Lithium-Ion Pouch Cells

A 2023 study analyzing eight commercial lithium-ion pouch cells demonstrated 14.7% capacity degradation over 800 cycles using controlled 1C discharge rates. Researchers correlated capacity fade with electrolyte depletion patterns observed through SEM imaging, establishing predictive models with ±1.2% margin of error across batch samples—valuable for quality assurance in high-volume production.

Hybrid Pulse Power Characterization (HPPC) for Dynamic Load Simulation

HPPC applies 10-second discharge/charge pulses to simulate real-world loads like EV acceleration and regenerative braking. Automotive OEMs report 92% correlation between HPPC-derived power metrics and actual vehicle performance, enabling precise battery sizing for target 0–60 mph acceleration profiles.

Designing Application-Specific Testing Procedures for Real-World Relevance

Custom protocols improve predictive accuracy by 40% for mission-critical applications. Examples include:

- Low-temperature logistics: Testing at -30°C with 2C discharge rates

- Grid storage: Implementing 72-hour rest periods between partial charge cycles

- Medical devices: Validating 99.99% charge/discharge consistency over 10,000 micro-cycles

These adaptations address industry-specific requirements while maintaining compatibility with ISO 12405-4 test frameworks.

Electrochemical Impedance Spectroscopy and Internal Resistance Analysis

Role of EIS in Diagnosing Battery Cell Health and Performance

Electrochemical Impedance Spectroscopy or EIS has pretty much taken over as the go-to method for checking out battery cells without damaging them. It helps spot when batteries start losing their ability to hold charge and tracks changes in how well they conduct electricity inside. The technique works by sending AC signals at different frequencies ranging somewhere between 0.1 Hz all the way up to around 100 kHz. This lets scientists measure things happening chemically within the battery such as how fast charges move around and how thick those pesky SEI layers get on electrodes. Most folks working with batteries these days rely heavily on EIS readings for figuring out health status because traditional tests just don't catch problems until they're already pretty bad.

Understanding Ohmic Resistance and Impedance Fundamentals

Ohmic resistance (RΩ) represents immediate voltage drop during current flow, while impedance (Z) incorporates both resistive and reactive components. Key distinctions:

| Parameter | Measurement Scope | Frequency Dependency |

|---|---|---|

| Ohmic Resistance | Ionic/electronic conduction losses | None |

| Impedance | Kinetic/diffusion limitations | Strong |

EIS separates these parameters through Nyquist plot analysis, revealing dominant degradation modes such as electrolyte drying or electrode cracking.

Case Study: EIS Analysis of Degradation in Lithium-Ion Pouch Cells

According to a recent study published in Frontiers in Materials back in 2025, EIS turned out to be pretty good at keeping track of how lithium ion pouch cells age over time. The research team set up their experiment with a three electrode system, applying those 10 millivolt AC signals across frequencies ranging from 0.01 Hz all the way up to 100,000 Hz. What they found was quite interesting actually - after about 500 charge cycles, there was a noticeable 34% jump in what they call charge transfer resistance. When they ran their simulations after testing, it seemed clear that this resistance spike came down to two main factors: the solid electrolyte interphase layer getting thicker and bits of active material starting to come loose from where they should be. These findings give manufacturers something real valuable to work with if they want to make batteries last longer before they start failing.

Emerging Rapid-Test Techniques: Pulse and AC Impedance Methods

Pulse-based EIS variants now deliver 87% faster testing than traditional methods by:

- Using multi-sine waveforms (1–1000 Hz simultaneous signals)

- Limiting test duration to <15 minutes per cell

- Maintaining <5% error margin vs. standard EIS

This enables inline quality control in gigafactories, where one EV manufacturer reported a 62% reduction in cell grading time without sacrificing diagnostic accuracy.

Optimizing Frequency Selection and Data Interpretation in EIS

Strategic frequency bracketing improves diagnostic accuracy:

- Low frequencies (0.01–1 Hz): Track lithium-ion diffusion limitations

- Mid-range (1–1000 Hz): Detect electrode/electrolyte interface changes

- High frequencies (>1 kHz): Isolate connector/collector resistance

Advanced equivalent circuit modeling tools now automate 92% of parameter extraction workflows, reducing interpretation time from hours to minutes and enhancing reproducibility across testing environments.

Impact of Test Conditions on Battery Cell Results

How Test Conditions Influence Battery Performance Variability

The performance numbers for battery cells can change quite a bit depending on how they're tested. Factors like temperature changes, different discharge speeds, and what percentage of charge remains in the cell can actually cause variations of around 30% in standard testing scenarios. Research published in the Journal of Energy Chemistry back in 2021 found something interesting about NMC cells specifically. When these batteries were drained at twice the normal speed (2C) instead of half speed (0.5C), their usable capacity dropped by about 15%. The reason? Basically because ions don't move through the material as quickly during fast discharges, and there are some challenges with getting those charges transferred properly within the cell structure.

Effects of Temperature, Discharge Rate, and State of Charge on Performance

Extreme temperatures create two major problems for batteries. When it gets too hot, electrodes break down faster because of unwanted chemical reactions, leading to about 3 to 5 percent less capacity for every 10 degrees Celsius above 25°C. Cold weather is equally problematic since ionic resistance jumps by around 200 to 300 percent in standard lithium-ion systems when temperatures drop below freezing. A study published recently by Capkova and colleagues found something interesting about lithium-sulfur batteries. At minus 20°C, these pouch cells only kept about 60% of what they could hold at normal room temperature, mainly because the electrolyte becomes thicker and harder to work with. The effects get really bad in high energy density cells too. Quick discharge rates like 5C pulses cause voltage drops that go over 20% in those NMC graphite setups, which makes them pretty unreliable under stress.

Case Study: Low-Temperature Performance Testing of Commercial Cells

A comparative analysis of eight commercial 18650 cells at -10°C showed:

| Chemistry | Capacity Retention | Power Output Reduction |

|---|---|---|

| NMC622 | 68% | 55% |

| LFP | 82% | 40% |

| LTO | 95% | 15% |

The lithium titanate (LTO) cells demonstrated superior low-temperature resilience due to their zero-strain crystal structure and higher electrolyte conductivity, aligning with 2023 Applied Energy research on lithium-ion cold-weather performance.

Testing Under Restricted Conditions for Safety and Compliance Validation

Regulatory protocols like UN38.3 mandate extreme condition testing, including thermal shock cycling (-40°C to +71°C) and altitude simulation (11.6 kPa). These tests identify failure modes such as separator collapse in lithium polymer cells during rapid depressurization, ensuring safe transport and operation under stress.

Controlling Variables for Reproducible and Accurate Battery Cell Analysis

Modern test standards demand tight controls these days, typically around plus or minus half a degree Celsius for temperature and about one percent accuracy for current measurements to keep results consistent across different labs. Research published in Frontiers in Energy Research back in 2025 showed something interesting too. When clamping forces in those cell fixtures vary beyond two Newton meters, it actually changes contact resistance by as much as eighteen percent. That's why getting mechanical setup right matters so much in testing environments. Labs that maintain stable environmental factors along with proper mechanical alignment tend to produce far better data that stands up to scrutiny and repeats reliably when tests are run again later on.

FAQs

Why is battery cell evaluation important?

Battery cell evaluation helps prevent major issues with technology like electric vehicles and energy storage solutions. It allows engineers to predict lifespan and detect early problems, enhancing reliability and safety.

What are the core parameters for battery evaluation?

Capacity, open-circuit voltage, and internal resistance are fundamental metrics for battery evaluation, affecting energy storage capability, state-of-charge, and power delivery efficiency.

How do different battery chemistries influence performance?

Different chemistries like NMC, LFP, and LTO offer trade-offs between energy density, longevity, and stability, making them suitable for specific applications.

What are some standard battery testing methods?

Common methods include galvanostatic charge/discharge cycling, electrochemical impedance spectroscopy (EIS), and hybrid pulse power characterization (HPPC) for simulating real-world conditions.

Table of Contents

-

Key Performance Parameters in Battery Cell Evaluation

- Why performance characterization of lithium-ion battery cells matters

- Fundamental electrochemical parameters: Capacity, open-circuit voltage, and internal resistance

- Performance benchmarking across chemistries: NMC, LFP, and LTO

- Best practices for reliable and comparable battery cell testing

- Industry shift toward standardized performance evaluation protocols

-

Core Testing Methods for Battery Cell Performance

- Overview of Common Battery Testing Methods Across Industries

- Measuring Capacity Through Galvanostatic Charge/Discharge Cycling

- Case Study: Capacity Testing in Lithium-Ion Pouch Cells

- Hybrid Pulse Power Characterization (HPPC) for Dynamic Load Simulation

- Designing Application-Specific Testing Procedures for Real-World Relevance

-

Electrochemical Impedance Spectroscopy and Internal Resistance Analysis

- Role of EIS in Diagnosing Battery Cell Health and Performance

- Understanding Ohmic Resistance and Impedance Fundamentals

- Case Study: EIS Analysis of Degradation in Lithium-Ion Pouch Cells

- Emerging Rapid-Test Techniques: Pulse and AC Impedance Methods

- Optimizing Frequency Selection and Data Interpretation in EIS

-

Impact of Test Conditions on Battery Cell Results

- How Test Conditions Influence Battery Performance Variability

- Effects of Temperature, Discharge Rate, and State of Charge on Performance

- Case Study: Low-Temperature Performance Testing of Commercial Cells

- Testing Under Restricted Conditions for Safety and Compliance Validation

- Controlling Variables for Reproducible and Accurate Battery Cell Analysis

- FAQs