Understanding the Hazards of Lead Acid Batteries

Chemical Composition and Toxic Components in Lead Acid Batteries

Lead acid batteries are made with lead plates sitting in sulfuric acid solution, and both components create serious problems for the environment and human health. The average 12 volt battery holds somewhere around 18 to 21 pounds of lead, which makes up roughly 60 percent of the total weight, along with about one to two gallons of very strong acid inside. If these batteries get broken or cracked open, they let out dangerous heavy metals plus acidic fumes that eat away at buildings and other structures while also causing real trouble for people's lungs and breathing systems.

Environmental and Health Risks of Improper Battery Disposal

When batteries aren't disposed of properly, they often leak lead into groundwater. We're talking about concentrations as high as 5.7 micrograms per liter, which is actually 38 times above what the EPA considers safe. Acid leakage from discarded batteries can make soil pH drop dramatically between 2.0 and 4.0 something similar to how strong vinegar tastes. This kind of extreme acidity really messes with the tiny organisms living in the soil. According to research from the CDC, kids exposed to lead tend to have their IQ scores drop around 4.25 points on average. For grown-ups, there's even worse news: studies show people with lead exposure face nearly double the risk of dying from heart problems compared to those without such exposure.

Classification of Lead Acid Batteries as Hazardous Waste Under EPA Standards

The EPA classifies lead acid batteries as D008 hazardous waste under RCRA Title 40, requiring:

- Recycling rates ≥ 99% (industry achieved 98.9% in 2023)

- Sealed secondary containment for storage

- Mandatory transporter manifests

Violations carry fines up to $81,540 per incident under the 2024 Clean Air Act amendments.

Case Study: Groundwater Contamination From Abandoned Lead Acid Batteries

A 2022 Michigan DEQ study detected 1,200 ppm lead near an illegal dump—40 times the safe level—with contamination spreading 1.3 miles downstream within 18 months. Remediation cost $2.7 million, underscoring the need for specialized handling to prevent ecological damage.

U.S. Regulations and Compliance for Lead Acid Battery Disposal

EPA Guidelines and Federal Requirements for Lead Acid Battery Handling

The Resource Conservation and Recovery Act (RCRA) makes it illegal to throw lead acid batteries into landfills, and requires stores to take back old batteries for free whenever someone buys a new one. This rule actually comes from another law passed way back in 1996 called the Mercury-Containing and Rechargeable Battery Management Act. For businesses handling more than 100 kilograms of these batteries each month, they need to sign up with the EPA and can't keep them stored for longer than twelve months. If companies ignore these rules, they could face serious fines running as high as eighty-one thousand five hundred forty dollars every single day they're out of compliance.

State-Specific Regulations and International Disposal Standards

Federal laws establish baseline requirements, but some states have gone way beyond those basics. Take California and New York as examples where regulations are much tougher. Looking at specific cases, Arizona has Title 44-1323 which actually demands that every battery must carry a recycling label. The state also slaps hefty penalties on anyone caught dumping batteries illegally, with fines reaching as high as ten thousand dollars. When we look across borders, the European Union rolled out their 2023 Battery Regulation aiming for 90 percent lead recovery by 2027. That's better than what happens in most parts of America where only about 86 percent gets recycled according to Battery Council International data from last year. These numbers show just how much interest there is worldwide in creating systems where materials get reused instead of tossed away after one use.

Enforcement Gaps and Challenges in Hazardous Waste Management

The EPA's own audits reveal that around one third of auto repair shops aren't following proper storage rules despite existing regulations. Looking at enforcement data from 2022 shows an interesting gap between action taken and actual violations found there were 1,200 infractions recorded but only 230 resulted in penalties. This points to serious limitations in regulatory oversight capabilities. Things get even worse in rural communities where qualified hazardous waste inspectors simply aren't available enough to make a difference. According to the National Waste & Recycling Association stats from last year, over 40% of these places store materials incorrectly. With such glaring holes in compliance monitoring, it makes sense why many experts are pushing for better cooperation between different levels of government and more transparent ways for the public to track what's happening with environmental regulations across the country.

Safe Storage and Handling Practices for Used Lead Acid Batteries

Best practices for storing and transporting used lead acid batteries

Store batteries upright in non-conductive containers to prevent leaks and short circuits. Maintain temperatures below 80°F (27°C) and humidity under 30% to minimize corrosion, and keep them away from flammable materials. During transport, use vibration-dampening restraints to protect casings. Industry studies show proper storage reduces premature failure risk by 62%.

Handling damaged batteries to prevent acid leaks and exposure

Use acid-neutralizing kits—containing baking soda or commercial absorbents—when dealing with cracked or leaking batteries. Immediately transfer compromised units to secondary containment and label them clearly. Avoid stacking damaged batteries, as 78% of workplace exposure incidents stem from stacking-induced fractures.

Protective equipment and containment solutions for battery handlers

Essential PPE includes:

- Acid-resistant gloves (minimum 0.4mm thickness)

- Full-face shields meeting ANSI Z87.1 standards

- PVC aprons rated for sulfuric acid resistance

Spill containment pallets should hold at least 110% of the largest battery’s volume, with weekly inspections to ensure structural integrity.

Recycling Lead Acid Batteries: Process, Benefits, and Innovations

Step-by-Step Process of Recycling Spent Lead Acid Batteries

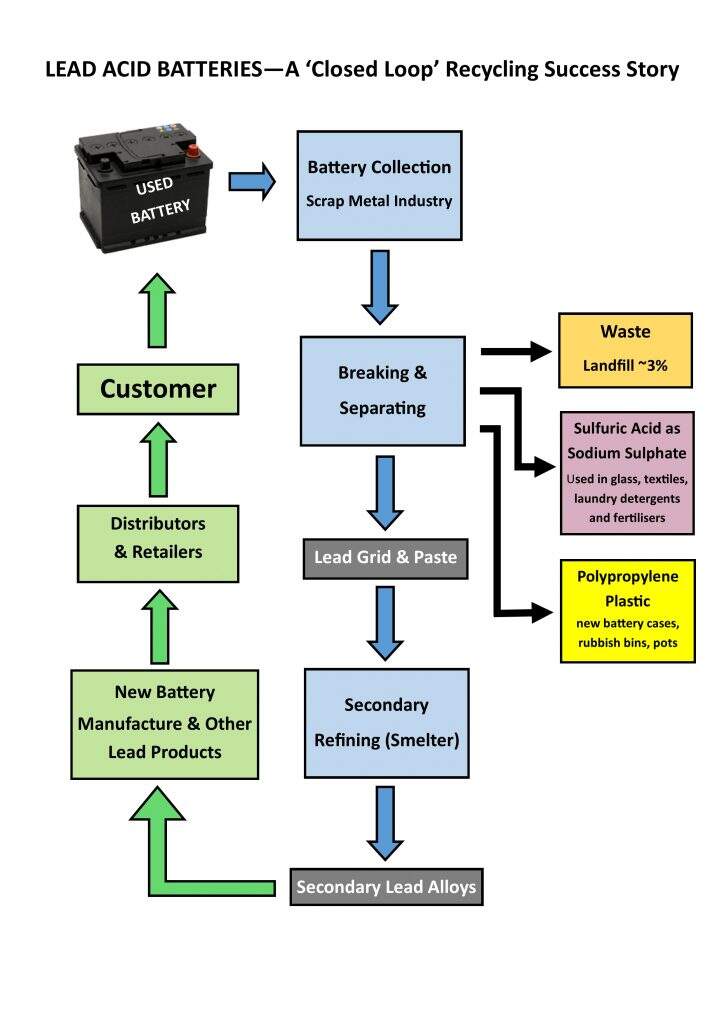

When certified recyclers get started, they first gather old batteries while wearing protective equipment to keep from getting exposed to battery acid. Once collected, the batteries go through a mechanical shredding process that breaks them down into different parts. The plastic shells get turned into pellets for later use, the lead grids melt down into solid blocks called ingots, and the dangerous sulfuric acid either gets neutralized or transformed into something called sodium sulfate which industries can actually use. The whole recycling loop manages to recover around 99 percent of all materials, though this number depends on how well everything runs smoothly throughout the entire process.

Material Recovery Rates and Environmental Benefits of Recycling Lead Acid Batteries

Modern recycling achieves 97% material recovery, diverting 2.4 million tons of lead from landfills annually. It reduces mining demand by 75% compared to virgin production and cuts greenhouse gas emissions by 65% per unit. Recycling one battery saves enough energy to power a home for three hours and prevents 18 kg of CO₂ emissions.

The Recyclability Paradox: High Potential vs. Low Public Participation

Despite a mature recycling infrastructure, only 68% of consumers consistently return used lead acid batteries. This occurs even though 94% of auto shops offer free take-back programs, indicating a critical need for public education on accessibility and environmental impact.

Emerging Innovations in Lead Acid Battery Recycling Technologies

New methods include biodegradable citric acid solutions that extract lead with 98% efficiency (Fatima et al., 2024), eliminating hazardous byproducts from traditional smelting. Advances also feature AI-powered robotic disassembly systems processing 800 batteries per hour and hybrid recycling plants recovering both lead and cobalt from mixed battery streams.

Finding Certified Recycling Programs and Services

Locating Certified Lead Acid Battery Recycling Centers Near You

Over 99% of lead acid batteries are recyclable through certified channels (EPA, 2023). Consumers can find approved facilities via the RCRAInfo database, a government-endorsed tool. Most states require automotive retailers and battery sellers to accept used units at no cost—this policy diverts 48 million batteries from landfills each year.

Retail Take-Back Programs and Auto Shop Involvement

Major auto parts retailers operate widespread drop-off networks, often offering store credits for returned batteries. These programs recovered 1.8 million metric tons of lead in 2023. Repair shops increasingly partner with certified recyclers, using spill kits and secure transport protocols to ensure safe handling during service replacements.

Municipal Hazardous Waste Events and Mobile Collection Options

Cities like San Francisco achieve 93% battery recovery through community collection events and mobile hazardous waste units, which are especially effective in rural areas. Seasonal drives typically process 200–500 batteries daily while educating residents on proper temporary storage to prevent terminal corrosion.

FAQ

1. What makes lead acid batteries hazardous to health and the environment?

Lead acid batteries contain lead and sulfuric acid, which can be toxic to humans and the environment if not handled properly. Lead can contaminate water and soil, while sulfuric acid can lead to harmful fumes.

2. How does improper disposal of lead acid batteries affect the environment?

Improperly disposed batteries can leak lead into groundwater and cause soil acidification, leading to harm to ecosystems and human health. Contamination from abandoned batteries can spread and require costly remediation efforts.

3. What are the regulations for disposing of lead acid batteries in the U.S.?

Under the Resource Conservation and Recovery Act (RCRA), it’s illegal to dispose of lead acid batteries in landfills. Retailers must accept old batteries when a new one is purchased, and businesses must comply with storage and handling regulations.

4. How effective is the recycling process for lead acid batteries?

The recycling process for lead acid batteries is highly efficient, achieving around 97-99% material recovery, thus reducing landfill waste and lowering greenhouse gas emissions by 65% per unit of material recycled.

5. What innovative technologies are being used in lead acid battery recycling?

Emerging innovations include the use of biodegradable citric acid for lead extraction and AI-powered systems for robotic disassembly. These improve efficiency and safety in the recycling process.

Table of Contents

- Understanding the Hazards of Lead Acid Batteries

- U.S. Regulations and Compliance for Lead Acid Battery Disposal

- Safe Storage and Handling Practices for Used Lead Acid Batteries

- Recycling Lead Acid Batteries: Process, Benefits, and Innovations

- Finding Certified Recycling Programs and Services

-

FAQ

- 1. What makes lead acid batteries hazardous to health and the environment?

- 2. How does improper disposal of lead acid batteries affect the environment?

- 3. What are the regulations for disposing of lead acid batteries in the U.S.?

- 4. How effective is the recycling process for lead acid batteries?

- 5. What innovative technologies are being used in lead acid battery recycling?